The Caterpillar EC210 VECU is a cutting-edge electronic control unit that plays a pivotal role in the operation of this popular excavator. This intelligent system monitors various aspects of the machine, ensuring smooth and optimized operation.

The VECU communicates with a network of sensors and actuators throughout the excavator. It processes data from these components to control engine speed, hydraulic flow, and other critical parameters in real-time. This dynamic control system allows the operator to optimize fuel efficiency, reduce wear and tear on components, and improve overall productivity.

The Volvo EC210 VECU also features a range of monitoring capabilities.

Operators can use the onboard display to monitor real-time here metrics and identify potential problems. This preventative maintenance approach helps to minimize downtime and guarantee the long-term reliability of the excavator.

Troubleshooting Guide for Volvo Excavators EC210 VECU

This detailed troubleshooting guide will help you resolve common issues with the Volvo Excavator EC210's Vehicle Electronic Control Unit (VECU). The VECU is a vital component that controls various functions of the excavator, and any malfunction can severely impact its performance.

- First checking the VECU's electrical connections.

- Verify all wires are securely attached.

- Employ a multimeter to check for voltage at the VECU's input terminals.

Examine the excavator's repair guide for detailed information on VECU maintenance. Note all symptoms and any fault codes that are displayed.

Unlocking the Potential of the Volvo EC290's ECU System

The Volvo EC290 is a forceful machine known for its efficiency. At the heart of this powerhouse lies its sophisticated Electronic Control Unit (ECU) system. This intricate network of devices gathers data from various aspects of the excavator, analyzing it to enhance performance and fuel efficiency. By tapping into the power of this ECU system, operators can secure a deeper understanding into their machine's functions, leading to refined operating techniques.

- Secure a deeper understanding of your machine's performance

- Enhance fuel efficiency through ECU adjustments

- Tap into hidden potential for increased productivity

Testing Volvo Truck ECUs: A Comprehensive Guide

Embark on a journey to grasp the intricacies of simulating Volvo truck Electronic Control Units (ECUs). This comprehensive guide explains the fundamental concepts and methodologies required in creating accurate replicas of these critical automotive components. Dive into the world of software designed for ECU simulation, discover the obstacles faced by engineers, and uncover best practices for effective ECU simulation. Whether you are a student seeking knowledge in automotive engineering or a professional engaged in the development of cutting-edge truck technology, this guide offers invaluable insights to propel your understanding forward.

- Grasp the role of ECUs in modern Volvo trucks.

- Discover the various types of ECUs and their unique functions.

- Gain knowledge of common ECU simulation tools and platforms.

- Create realistic ECU models for testing purposes.

- Resolve real-world challenges encountered during ECU simulation.

State-of-the-art Diagnostics for Volvo Construction Equipment ECUs

To maximize uptime and efficiency in contemporary construction environment, accurate and rapid diagnostics of Volvo Construction Equipment ECUs are paramount. Leveraging the latest technologies, these advanced diagnostic tools provide in-depth insights into ECU functionality, enabling technicians to efficiently pinpoint and resolve issues. Through sophisticated data analysis and fault code interpretation, mechanics can diagnose a wide range of problems, from subtle sensor errors to complex software glitches.

- Functions of advanced diagnostics include:

- Real-time data monitoring of ECU parameters

- Accurate fault code retrieval

- Guided troubleshooting assistance

- Archived data analysis for trend identification

These tools not only minimize downtime but also enhance repair processes, ultimately leading to enhanced productivity and cost savings for construction operators.

Optimizing Performance of Volvo EC210 and EC290 VECUs

Achieving peak performance from your Volvo EC210 or EC290 excavator hinges on the robustness of its Vehicle Electrical Control Unit (VECU). These powerful machines demand meticulous care to ensure optimal performance. To unlock the full potential of these excavators, consider implementing strategic performance optimization techniques. This can involve fine-tuning key parameters within the VECU software, utilizing advanced diagnostic tools to detect potential issues, and incorporating best practices for preventative upkeep. By taking a holistic approach to VECU performance optimization, you can improve fuel efficiency, reduce downtime, and ultimately boost the overall productivity of your Volvo excavator fleet.

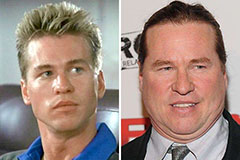

Val Kilmer Then & Now!

Val Kilmer Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!